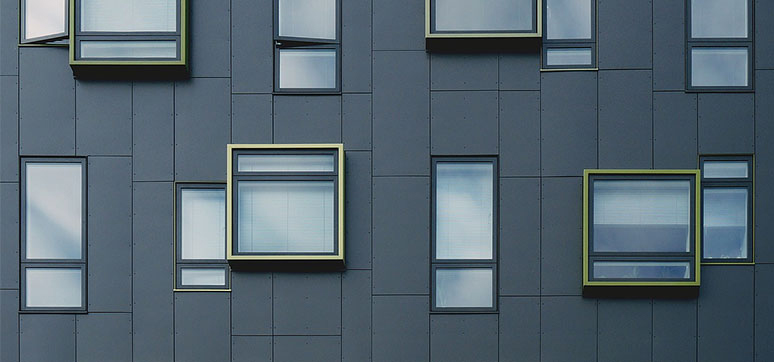

Aluminium composite panel is a thin flat panel in which a non aluminium core is added and compressed between aluminium panels. Its strength and durability is promising and thus, is widely used as a cladding material for buildings.

The ACP cladding sheets are a cheaper cladding option and ACP cladding suppliers offer different types of ACP cladding sheets are the price range of 70/sqft – 500/sqft.

The aluminium composite panel cladding sheets are long lasting and provide a rich look to the interior as well as exterior of houses and buildings. The ACP sheet suppliers supply cladding sheets for commercial buildings, housing projects, restaurants, hotels, schools and such projects. There are ample of ACP cladding sheet suppliers throughout India as, India is the 5th largest producer of aluminium in the world. Suppliers offer ACP glazing sheets, these sheets are available in different shades and textures. The ACP sheets are developed while using number of films and coating material which makes it fire proof, light weight, termite resistant and highly recyclable. For a rustic feel and rich interior/exterior, choose ACP cladding sheets and make your property look ravishing this season.

Here are the top ACP Sheet manufacturers in India:

- Eurobond (Euro Panel Products Pvt. Ltd.)

- Wonder Alu Board services

- Alstrong Enterprises India Pvt Ltd

- Front Elevation India

- Future Good Flooring

- Sri Kala projects

- D-Glaze

- Aluminium Enterprises

- Plywaala

- Designing future

- Loom Clad

- Aludecor Lamination Pvt Ltd

- Alstone Industries Pvt Ltd

- Imperia Décor industries

- Akshar Aluminium & Furniture

- ALUCON Metal

- Setwin Engineers

- Wilmen Enterprises

- Viva Composite Panel Pvt Ltd

- Baba Asuda Ram sheesha & Plywaala

- ALUPHA TECH

- RICH STEEL

- Reynobond

- STAR ENGINEERING COMPANY

- Alucobond – 3A composites India Pvt Ltd

Contact the supplier to get price quotation in your city.

Aluminium Composite panels/sheets are one of the most popular sustainable materials that are used worldwide for the building construction industry. In India the Aluminium Composite panel industry has an annual volume of more than Rs. 1500 crores and a requirement of more than 400 million square feet. The industry is growing upswing at a steady rate of about 28% to 30% per year. They are sandwich panels comprising of two aluminium sheets bonded to an organic mineral filled inner core material which could be of high density or low density. The light weight, aesthetics, good acoustic properties, fire rated properties easy installation and very low wastage make it the material of today. ACP is highly resistant to acids, alkalis, pollution and has very good sound and heat insulation properties. ACP sheets helps in energy conservation by the building as per the ECBC code. In India ACP became very popular in the last decade but the market is dominated by some key players. Over a period of time the panels are becoming more innovative, sustainable, and durable with new technology along with a continuous research towards improvement. Read also : What is ACP (Aluminium Composite Panel)?

Top ACP Sheet Manufacturers

With more than 25 brands in India the top Aluminium Composite Panel ACP manufacturers are -

ALSTRONG

Alstrong is a product of the ‘World Window Group’. The company was incepted in the year 2001; it is headquartered in Delhi and has its manufacturing unit in Jammu. The company manufactured 1 lac square feet of ACP in the year 2001 which has currently escalated to around 50 million square feet per annum.

The company uses leading Japanese and Korean technology to create Aluminium Composite panels of international standards.Alstrong is available in various designs, colours and textures and lays a lot of emphasis on R & D, efficiency, consistent production. The Coil coating integration method is adopted for the painting of Aluminium Composite Panels.

A customized panel as per design can be manufactured and finished within 10 days by Alstong.

Basic features of Alstrong Composite Panels

Year of Inception - 2001 Alloy used - 3000 series (1100, 3003, 3105, 5005) Core Material – 70% LDPE (Low Density Polyethylene) +30% HDPE (High Density Polyethylene) Panel Thickness – 4mm (reference thickness) Weight - 5.5 kg/m2 Coating – Kynar 500 PVDF coating Coating thickness – Solid colors (25 microns), Metallic Colours (35 microns Adhesive Film - Du Pont adhesive film Warranty - 10 years for 2 coats and 20 years for 3 coats

ALUDECOR

Aludecor was incepted in the year 2004 and is a product of the HMB Group. The brand is headquartered in Kolkata and its manufacturing unit is spread over 25,000 square meters in Haridwar. The Company has a very good production capacity and is targeting an annual revenue of more than 500 crores in the next two years.

Aludecor is a very good quality product which uses the latest technology after quality research. It is the first company in India to use the technology of Double Coat Double Bake method which ensures the long term longevity of the product. A very strict vigilance and checking method is adopted to maintain the standard of quality. It is available in a wide variety of colours and textures. Copper Aluminium Composite panels are one of the additions of innovative panels in their product range.

Aludecor follows the green industry norms and pays special attention to sustainability. The major steps taken as a step towards sustainability is the use of recyclable polyethylene and all the paint that is used on the Aluminium Composite panels is lead free. In addition the water that is released from the manufacturing plant goes through an effluent treatment plant as a step towards sustainability.

Basic features of Aludecor Composite Panels

Alloy used - AA3105 Core Material – Recycled LDPE (Low Density Polyethylene) Panel Thickness – 4mm (reference thickness) Weight - 5.5 kg/m2 Tensile Strength of Aluminium Composite Material – 40N/mm2 Coating – PVDF based fluorocarbon coating Coating thickness – Solid colors (25 microns), Metallic Colours (30-35 microns), three coats (30-35 microns) Adhesive Film - Du Pont -USA Warranty - 10 years

ALUCOBOND

3A Composites GmbH is the parent company of Alcuobond; it is highly popular and available worldwide. This company is the original leader of the market since the year 1969. In India the head office is in Mumbai and manufacturing unit in Maharashtra.

Alucobond is known for its high quality, unique appearance and is fire retardant. The product has a very good flatness, weather proof and impact resistant, high weather resistance, scratch resistant and does not break easily. The ACP material has a very high rigidity and very low weight.

The company lays great emphasis on sustainability with the use of recyclable and Eco-friendly materials. The product is available in a variety of colours, textures and finishes.

Basic features of Alucobond Composite Panels

Year of Inception - 2007 Alloy used - marine grade 5000 series which is highly corrosion resistant Core Material – Virgin LDPE (Low Density Polyethylene) Panel Thickness – 4mm ( reference thickness) Weight - 7.6 kg/m2 Tensile Strength of Aluminium Alloy - minimum 130 N/mm2 Coating – PVDF coating Coating thickness – 30microns -80 microns depending on product Adhesive Film - Warranty – 20 years

ALSTONE

Alstone was launched in the year 2004 and the company has it’s headquarter in Delhi. The company has two manufacturing plants one is in Dehradun-Uttaranchal and the other is near Jaipur in Rajasthan. In 2004 they had a production capacity of 0.5 million square meters which has escalated to more than 2.5 million square meters today.

Alstone offers one of the finest qualities of double layered aluminium skins. The product is first pre coated and then bonded with the non-toxic polyethylene core. They have an innovative range of products which are as per the current market trends. The raw materials used are very eco-friendly and sustainable.

Alstone has a very hi tech manufacturing unit where quality checks are conducted right from the purchase of raw material to the final delivery of finished products. The very closely monitored checks ensure that the final products are robust, durable, long lasting and are par with International standards.

Basic features of Alucobond Composite Panels

Year of Inception - 2004 Alloy used - 5005/3003/1100 grade Aluminium Alloy Core Material – LDPE (Low Density Polyethylene) Panel Thickness – 4mm (reference thickness) Coating – PVDF coating Warranty – 15 years

VIVA

Viva Composite Panels is one the big players in the Indian market. The company is headquartered in Mumbai and has a very big manufacturing unit with a capacity of 4 million square meters per month in Umbergaon - Gujarat. The company is using double extruders which has the doubled the production capacity and reduced the energy consumption by 25%.

Viva has a very good R & D department that introduces and offers new ranges to the customer on a regular interval. The company works in tandem with the emerging trends of the construction industry.

Basic features of Viva Composite Panels

Year of Inception - 2005 Alloy used - AA3000 series Core Material – LDPE (Low Density Polyethylene) Panel Thickness – 4mm (reference code) Weight- 5.2 kg/m2 Tensile Strength of Aluminium Panel - 38.35N/mm2 Coating – PVDF coating Coating thickness – 26.8 micron Adhesive Film - 50 microns thick adhesive lamination film for exterior panels and 40 microns thick film for interiors Warranty – 10 years

Reviewed by McCoy Mart

on

22:50

Rating:

Reviewed by McCoy Mart

on

22:50

Rating:

No comments: